Waste Heat Recovery for Combined Heat and Power

The Bloom Energy Server is compatible with heat capture technology for sustainable, resilient, price-predictable combined heat and power (CHP) designs.

The Bloom Energy Server with Heat Capture reaches a lifetime average efficiency of >90%

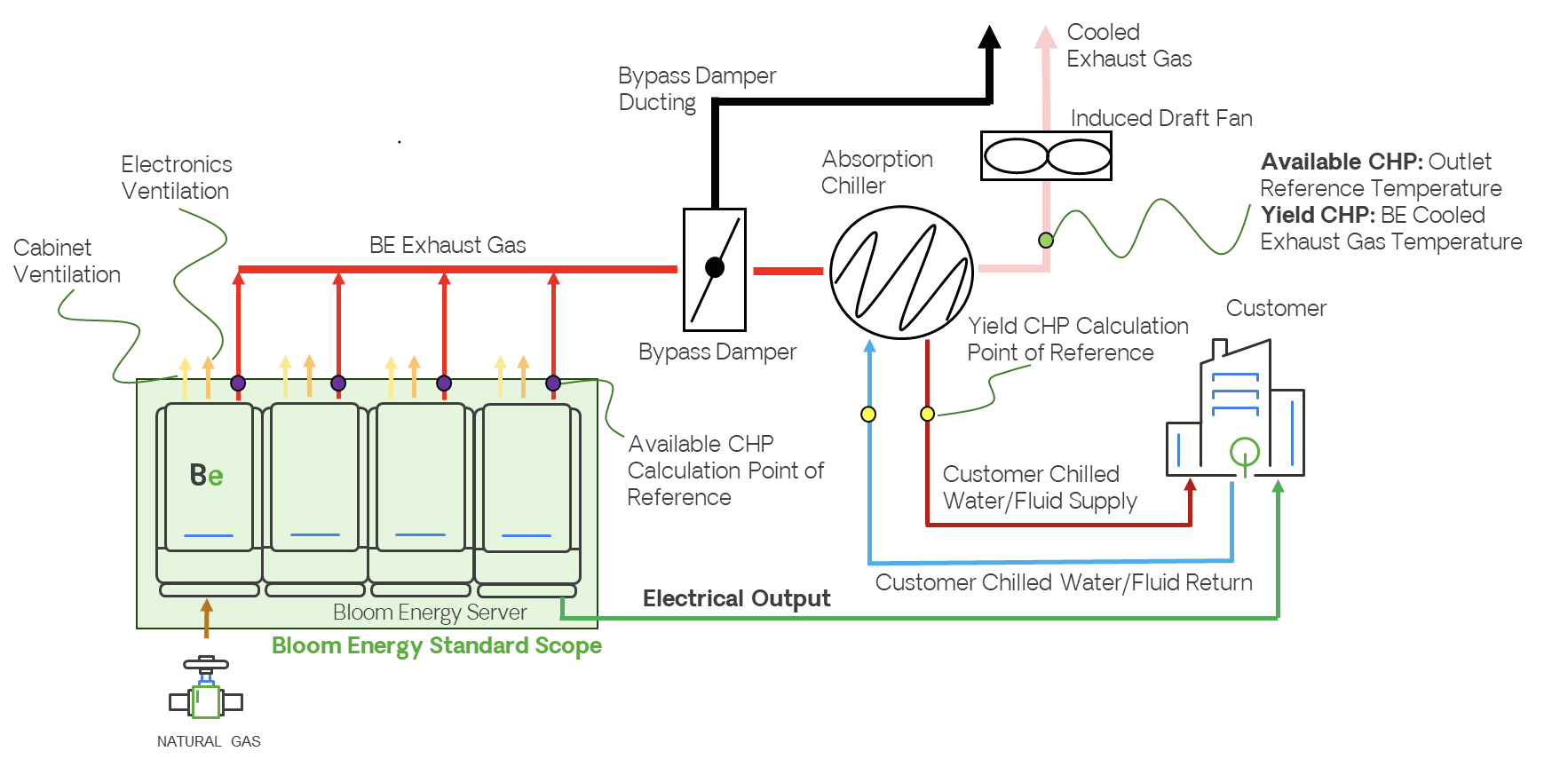

The Bloom Energy Server is compatible with Combined Heat and Power (CHP) systems, increasing system efficiency and improving economics. Bloom Energy is a world leader in fuel cell power generation. With a platform based on Solid Oxide technology, operating at temperatures above 800 ̊ C, the Bloom Energy Server can produce clean energy at one of the highest efficiencies in the market today. The high temperature cathode exhaust from the Energy Server can be channeled, allowing the resulting exhaust heat to be available for further use. Once captured, this high temperature heat can be utilized in various applications and to further increase the overall efficiency of the system.

Compared to combustion technologies and other fuel cell products, the Bloom Energy Server has one of the highest electrical efficiencies in the industry. By adding Heat Capture, the total system efficiency can reach a lifetime average efficiency of >90%.

1.8 MW Power Tower with Heat Capture Installation (3×600 kW)

The Bloom Energy Server with Heat Capture is scalable with building blocks starting at 220 kW to multiple MW systems, custom designed to fit any customer need. The Energy Server with Heat Capture can be installed at ground level or can be installed as a Power Tower with Heat Capture.

What is Bloom Energy’s Heat Capture Offering?

In order to maximize waste heat recovery, the Bloom Energy Server heat capture technology consists of mechanical exhaust adapters installed on the back of the Energy Server Power Modules that harness the cathode exhaust at two connection points for easy integration to heat capture systems.

Mechanical Exhaust Adapters for Waste Heat Recovery

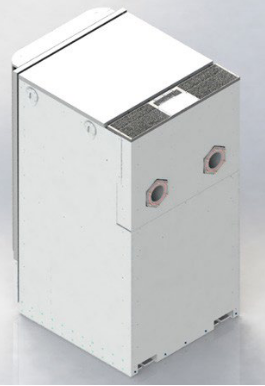

Bloom Energy provides mechanical adapters that allow heat capture on the cathode side of the fuel cell chemical reaction. Figure 1 shows the back of a standard Energy Server Power Module and an Energy Server Power Module that is equipped with Heat Capture. With the Heat Capture option, the exhaust heat exits the equipment at the back of the power module instead of the top and is easily transferred to a heat exchanger system.

Bloom Energy will work with heat recovery process experts to provide guidance for necessary connections, share drawings, and provide best practices for the design of the full CHP system.

Power Module without Heat Capture

Power Module with Heat Capture

Typical Applications of Heat Capture Technology

The Bloom Energy Server produces waste heat at an average temperature of > 350 ̊C. Common applications include using heat for boiler pre-heat, steam pre-heat, space heating, hot water generation, chilled water, biogas digesters, additional electricity generation, chemical processes that require heat, and district water heating. See Figure 2 for a typical application of a Bloom Energy Server working with a Heat Exchanger. These projections are calculated based on actual monitoring of existing Bloom Energy systems that are installed around the world.