Fuel cells were invented over a century ago and have been used in practically every NASA space mission since the 1960s. They are unique in that they can be used for a wide range of applications, from generating power for satellites and space capsules, to powering fuel cell vehicles like automobiles, buses, or boats, to generating primary or emergency backup power for buildings.

There are many types of fuel cells, but they all share a single common design and process: a negative electrode (an anode) and a positive electrode (a cathode) sandwiched around an electrolyte undergo an electrochemical reaction to produce an electric current. The electrolyte is an ion conductor that moves ions either from the fuel to the air or the air to the fuel to create electron flow. Electrolytes vary among fuel cell types, and depending on the electrolyte deployed, the fuel cells undergo slightly different electrochemical reactions, use different catalysts, run on different fuels, and achieve varying efficiencies.

For decades, experts have considered solid oxide fuel cells (SOFCs) to hold the greatest potential of any fuel cell technology due to their extremely high electrical efficiencies and low operating costs. In fact, SOFCs are likely to emerge as the fastest growing fuel cell segment over the next six years.

Bloom Energy is a leader in the SOFC industry, leveraging the technology to convert fuel into electricity at one of the highest efficiencies of any power solution today. The SOFCs generate primary power through Bloom Energy Servers, commonly known as ‘Bloom Boxes.’

So how do Bloom Energy’s SOFCs react with fuel and oxygen to generate electricity so efficiently?

Electrochemical Reaction: From Chemical Energy to Electrical Energy

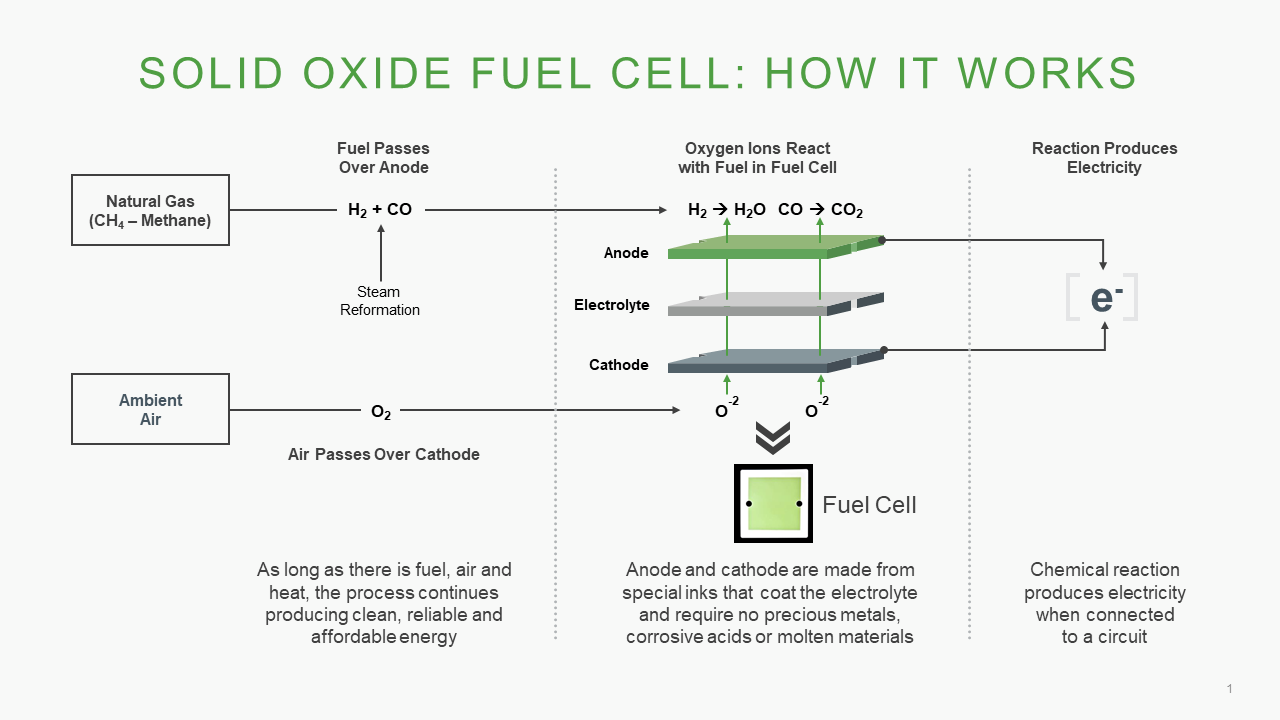

The electrolyte in SOFCs is unique; it’s a solid, ceramic material. The anode and cathode electrodes in Bloom’s fuel cells are special proprietary inks that coat the electrolyte. Unlike other types of fuel cells, no precious metals, corrosive acids, or molten materials are required to create Bloom’s SOFCs.

Operating at high temperatures inside the Energy Server (‘Bloom Box’), ambient air enters the cathode side of the fuel cell. Meanwhile, steam mixes with fuel (natural gas or biogas) entering from the anode side to produce reformed fuel. As the reformed fuel crosses the anode, it attracts oxygen ions from the cathode. The oxygen ions combine with the reformed fuel to produce electricity, steam, and carbon dioxide.

The steam that is produced in the reaction is recycled to reform the fuel. Because of this recycling process, Bloom’s fuel cells do not require water during normal operation. Conversely, thermal power plants require significant amounts of water for cooling. In fact, the number one use of water in the U.S. is for cooling power plants. To produce one megawatt per hour for a year, thermoelectric power generation for the U.S. grid withdraws approximately 156 million gallons of water more than our platform.

The electrochemical process also generates the heat required to keep the fuel cell warm and drive the reforming reaction process. As long as fuel and air are available, the fuel cells continue converting chemical energy into electrical energy, providing an electric current directly at the fuel cell site.

SOFCs are the first (and smallest) component manufactured for the Bloom Energy Server. The SOFCs are then combined to form a fuel cell stack and multiple stacks create a Server module (or ‘Bloom Box’). Four to six modules combine to form one 200-300kW Energy Server that produces power in a footprint roughly equivalent to that of half a standard 30-foot shipping container.

Because the Servers come together like building blocks, the modular design allows any number of systems to be clustered together in various configurations to form solutions from hundreds of kilowatts to many tens of megawatts.

How a Bloom Energy Server Works

Fuel Cells: A Blooming Power Solution

The Fuel Cell Industry Review estimates fuel cell shipments have grown at a 44% CAGR, or compounded annualized growth rate, since 2014 – paralleling the rise of solar and wind energy in earlier decades.

Klippenstein notes steadily-improving electrical efficiency and compatibility with natural gas infrastructure have underpinned solid oxide fuel cells’ own 24% CAGR, and that commercial readiness has been shown not only through Bloom Energy’s numerous Energy Servers, but through the estimated 70,000 household SOFCs currently deployed through Japan’s Ene-Farm program.

What’s driving this rapid growth? For starters, there’s a growing demand for energy diversification and the employment of alternative energy sources. In a post-climate change world where the threats of rising carbon emissions, extreme weather events, and a vulnerable grid are more pressing than ever, businesses and communities are demanding three things: more affordable electricity, more resilient power, and cleaner energy. Fuel cells are uniquely positioned to satisfy this niche.

The generation of electricity through an electrochemical reaction rather than fuel combustion means fuel cells are much cleaner and more sustainable than conventional combustion-based technology.

Fuel cells are clean in two ways: first, they avoid emitting harmful criteria air pollutants, including nitrogen oxide and sulfur dioxide, which have been linked to severe respiratory diseases and poor air quality worldwide, and second, they reduce greenhouse gas emissions as compared to the grid.

For example, the SOFCs that the ‘Bloom Box’ uses can run on natural gas, renewable biogas, or hydrogen. When the ‘Bloom Box’ runs on natural gas, the CO2 that is generated during the electrochemical process is 50% less than the carbon emissions generated by the U.S. grid. When the ‘Bloom Box’ runs on renewable biogas or hydrogen, emissions are carbon-neutral and zero-carbon, respectively.

While fuel cells offer a way to address the causes of climate change by reducing emissions, they also mitigate the consequences of climate change, including the more severe, frequent, and longer power outages caused by unprecedented weather events, like the Midwest polar vortex. Because fuel cells generally produce power on-site, right where it’s consumed, they offer increased electrical reliability and improved energy security.

Distributed power generation avoids the vulnerabilities of conventional transmission and distribution lines, providing a necessary buffer against power outages due to natural disasters, cyber threats, and other man-made disasters. Additionally, utilizing the below-ground pipeline infrastructure avoids the kind of cascading failures that often occur on the electrical grid.

Fuel cells are also ideal building blocks for microgrids; businesses that need to continue operating when the grid goes down like hospitals and healthcare facilities, high tech manufacturing centers, data centers, and retail stories are increasingly embracing microgrids with fuel cell tech for more reliable power.

Fuel cells are continually proving to be the best combination of efficiency, resiliency, and sustainability in the alternative energy generation landscape, and therefore are the leading power generation technology for businesses and communities.