The Challenge

Biotechnology and pharmaceutical manufacturers are increasingly susceptible to costly power disruptions.

In 2018, Hurricane Florence devastated the Carolinas, causing record flooding, wind gusts exceeding 100 mph, and over $16 billion in damages in North Carolina alone. The extreme winds felled trees, downed power lines, and forced hundreds of thousands to evacuate. But they also impacted manufacturing operations in the state.

Pfizer, a multinational pharmaceutical and biotechnology corporation, was forced to halt production at a key injectable drugs facility in North Carolina. Merck & Co. and Novartis also suspended operations in the state due to the storm.

Extreme weather events like Hurricane Florence have become increasingly common. And it’s not just regional areas where hurricanes, snowstorms or wildfires are more likely. Across the nation, outages caused by extreme weather events increased 70 percent between 2010-2019 over the previous decade.

Biotechnology and pharmaceutical manufacturing facilities are extremely vulnerable to interruptions in power. These types of buildings are vast, complex and resource-intensive, requiring critical elements such as around-the-clock temperature and air quality control to protect the highly sensitive nature of their products. Such structures are costly to build, operate, and maintain even before factoring in the cost of any unplanned downtime.

Grid-related power disruptions are one of the most pressing challenges threatening manufacturers today. Worse, these power events often lead to expensive delays in production, and costly setbacks to research, storage, or warehousing. Shutting off and turning back on a production line is a significant cost, that’s often difficult to calculate.

Quick Stats

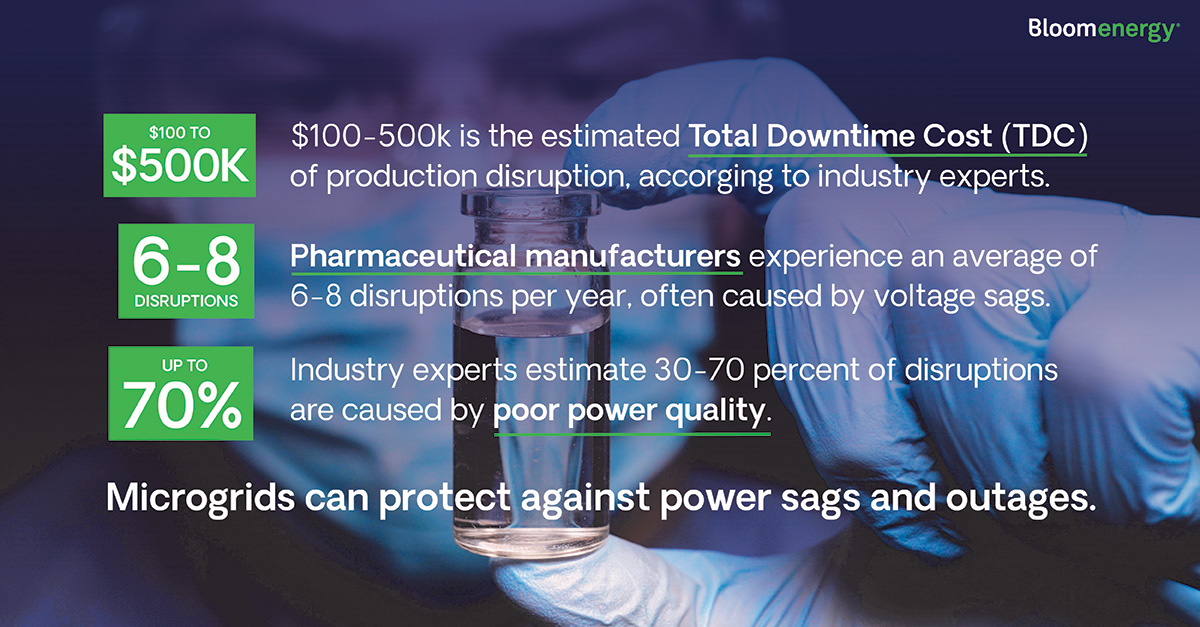

- Pharmaceutical manufacturers experience an average of 6-8 disruptions per year, often caused by voltage sags.

- Industry experts estimate 30-70 percent of disruptions are caused by poor power quality (Source: Rockwell Automation).

- Disruption to production in a pharmaceutical facility can cost up to $500,000 per hour of downtime, according to industry experts.

Eliminating Tradeoffs

As pharma and biotech companies look to address their critical resiliency needs, the growing ambitions of a net-zero future and the impacts of rising energy costs have elevated the importance of choice when it comes to power. Distributed generation is becoming critical to the energy transition, providing a clear path forward for those seeking to gain more control of their electricity supply.

Most distributed energy resources (DER) are self-sufficient, but they are not one size fits all. Technologies like wind and solar are great for their renewable profile but due to their inherent intermittencies, cannot practically solve resiliency challenges. Diesel generators have been the status quo back-up solution for decades. However, they are monolithic machines without inherent redundancy and produce over 40 toxic air contaminants, including a variety of carcinogenic compounds, during operation. Uninterruptible Power Supply (UPS) are also used to alleviate the effects of unexpected power disruption—for a short term, stop-gap solution. But UPS are expensive and often run on a limited supply of battery power. Resiliency decisions should not be made at the expense of environmental concerns and sustainability decisions should not ignore the importance of reliable energy supply.

What’s more, financial predictability has increasingly become top-of-mind, especially in recent months, where supply change shortages and sharply rising inflation have led to immediate and massive price surges on utility bills. These notable short-term increases have raised the stakes within an already complex purchasing environment and companies are actively looking for solutions that insulate them from this risk.

Meanwhile, many biotech and pharma companies are taking steps to implement renewable power by creating wind and solar farms.

Renewable power farms are often created in one of two ways: a company seeks to maximize sustainability with a cost-effective solar project that generates some power on-site for their operations, and is a cleaner option than the utility grid. But these projects often only power a fraction of a facility’s total kilowatt hours behind the meter.

The second option is to install a large-scale solar or wind farm off-site in a rural area, where it may send the power it generates into the grid creating Renewable Energy Certificates (RECs). These RECs can be retired against electrons still being purchased by facilities from their local utilities because there isn’t enough space onsite to remove the utility load with solar/wind. The farm generates clean energy, but the company’s facilities may still run on grid electricity.

Fuel Cell Microgrids

Fuel cells are an ideal solution for those seeking to gain more control over their electricity supply.

Fuel cells provide a critical foundation for building microgrids of varying complexity and can provide significant benefits to the communities, businesses, and utilities they are part of. This type of technology targets a customer’s 24/7 energy usage whereas technologies like solar or battery storage are intermittent.

Since fuel cells often generate power right where energy is being consumed, they can be deployed anywhere and are not dependent on the weather or encumbered by densely populated geography. Customers can tie their critical loads directly onto the fuel cells to provide UPS-quality power to avoid power quality issues as well as carry critical loads through long duration outages. For instance, Bloom’s microgrid platform powered one manufacturing center through a 5.5 day outage in California.

Moreover, our fuel-flexible platform addresses both the causes and consequences of climate change by using natural gas at the highest efficiency today, reducing water consumption and greenhouse gas emissions while improving local air quality. Plus, we are ready to advance decarbonization as renewables come online at scale.

The Solid Oxide Advantage

Solid oxide fuel cell technology, at the heart of the Bloom Energy Server, is uniquely effective in eliminating tradeoffs, providing an unparalleled combination of resiliency, sustainability, and cost predictability. It avoids the vulnerabilities of conventional transmission and distribution lines by generating power on-site, where the electricity is consumed.

Resiliency

As a critical, always-on microgrid solution, Bloom Energy Servers can operate alongside a main grid, but independently of it during a power outage. They stay online even when peak hours cause grid overload, or when distribution infrastructure is damaged—such as during Hurricane Florence. Because they receive fuel through the underground pipeline system, they are less susceptible to the impacts of extreme weather, enabling safe, continuous operation and avoiding costly consequences of unplanned downtime.

Sustainability

By converting natural gas, biogas, or hydrogen into electricity using an electrochemical reaction without combustion, we’re able to achieve an industry-leading 60 percent+ electrical efficiency while virtually eliminating NOx, SOx, and other harmful criteria pollutants from the environment.

Predictability

With the recent volatility in utility rates, low cost and predictable power are important factors for manufacturers facing cost scrutiny. Bloom Energy’s solid oxide platform not only protects against outage-related costs that can reach into the millions of dollars, but also enables customers to hedge against rate volatility and price escalation by fixing a large portion of their electricity cost, providing multiple financing options and flexible term length.

Conclusion

As biotech and pharma companies consider their future energy decisions, decarbonization commitments and resiliency needs will drive next steps.

Maintaining an environment that is productive, compliant, and ensures product integrity means taking every opportunity to mitigate business continuity risks and avoid production disruptions.

Bloom Energy is a trusted partner providing power generation solutions that enable energy security. Our unique onsite solid oxide platform produces power where it’s consumed, so customers avoid the threat of power disruptions and benefit from clean and affordable electricity.

Follow Bloom Energy on LinkedIn to learn more about ongoing projects, collaborations, and announcements.